Cookie/Biscuit Production Line

Product samples

Main Features

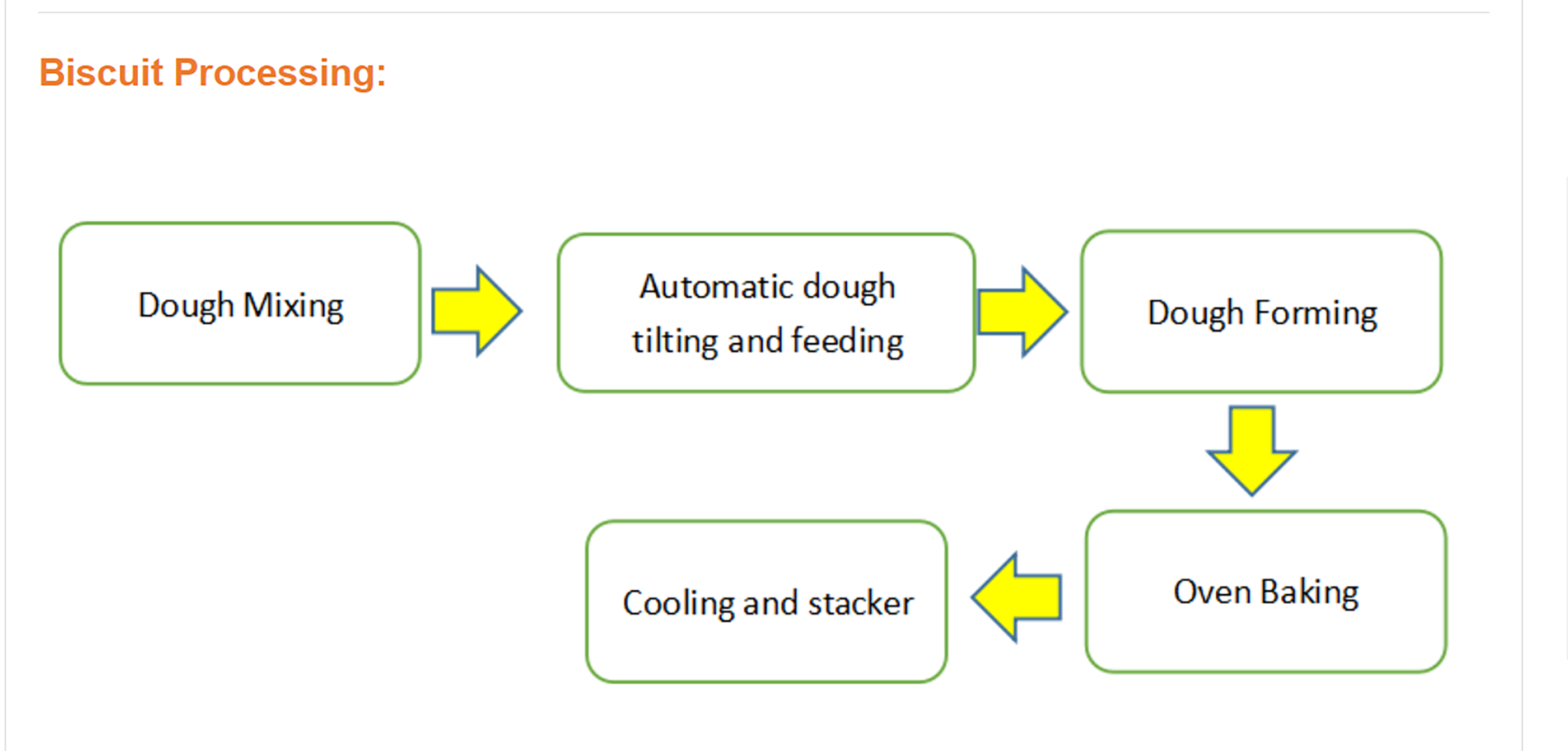

This is our own design automatic production line to produce cookies, biscuit, and varous cakes.

Fully automatic production line to produce cookies or bisbuit with production capacity from 40kg/h to 200kg/h. The production line can be customized according to the cutomer's requirements.

CAPACITY : FROM 40-200KG PER HOUR TO 60KG PER HOUR

INSTALLED POWER : 200-400kW / 3P / 50Hz

Main AC Motors and gear box by SEW / SIEMENS.

Industrial Bearings by NSK.

Cylinders by YSC.

Electrical Units by Schneider / SIEMENS.

Main Equipment

Mixer

Features: Horizontal mixer is used for dough processing. After the mixing & rolling, the dough would be the smooth surface, flexible, rubbery and extensible. Model of mixer works for soft and hard biscuit dough.

Parameters

- Mixing volume:50kgs/time. Bowl volume:100L

- Single blade, S shape.

- Bevel-U shape bowl with push-pull cover

- Working speed: 40r/min

- Power: 3.12KW

- Dimension:1250*550*1020

- Power driven pouring

- Bowl, mixer shaft and stirrer are s/s

- 304# s/s outer cover and chromed sideboard

- Motor and speed reducers by SEW

- Scram button and limit switch installed

- Perfect cable arrangement & Alu. wire-casing

- SCHNEIDER control apparatus

- NSK bearing

Single color wire cutting cookie machine

Technical Parameters

Model and corresponding mold spacing and quantity:

Model:400mm, model space:58.5mm, Number of molds:7pcs

Forming method: wire cutting; max. working times: cutting 100 times/min

Biscuits weight deviation: ±4% (each 5 cookies are weighed); pass rate: 98%

Production speed: Determined according to the oven length and baking time of the production line

Energy requirements: Determined according to customer needs (generally 380V/50Hz), total power: about 4KW

Material standard

The side board is made of Q235 carbon steel material, the thickness after processing is 20mm, and the surface is plated with hard chrome.

7050 aluminum alloy material for the side plate, connecting plate and cutting arm of the machine head, the surface is treated with Teflon

The gear pump are made of imported food grade nylon material; the pump body material is made of 7075 aluminum alloy, and the surface is treated with Teflon

The cutting funnel plate uses 7050 aluminum alloy, and the surface is treated with Teflon

The cutting mold uses imported food grade POM material

The covering, pallet and hopper are made of SUS304 stainless steel

Feeding forced roller diameter: Ø133, the material is made of SUS304 stainless steel

This machine uses 3 sets of servos; the servo motor uses Schneider, and the reducer uses Taiwan brand precision planetary helical gear reducer

Features

This machine is mainly used for the forming of high-fat cookies and cakes

Feeding by the gear pump, precise control, small deviation of biscuit weight;

Feeding forced rollers, gear pump and cutting are driven by servo motors, independently controlled respectively

The parameters such as the speed of the forced roller, the gear pump, and the cutting are controlled by the touch screen, which is easy to operate

The gear pump assembly adopts the worm gear clamping method, which is convenient for dis-assembly, cleaning and replacement, and simple operation

The cutting die assembly is clamped by an eccentric wheel, which is convenient for disassembly, cleaning and replacement, and simple operation

The cutting assembly adopts a cam linkage mechanism, and it is steady

Equipped with a mold trolley to assist in changing molds, which facilitates the removal of material pump components and cutting mold components for cleaning(charge extra)

The height between the belt and the mold can be adjusted conveniently and quickly by the handle, so that the biscuits can fall on the conveyor belt smoothly and neatly after being cut.

The surface of the main structural parts are plated with hard chromium, which is not easy to rust.

Electrical Oven

- Features: It is the baking equipment of the biscuit line, baking biscuit by thermal radiation,making biscuit with fine color and flavor.Parameters:heated by quartztube thermal radiation

- zone: generally divided by 1-3 zones according to the length of oven, each zone control temperature automatically, temperature digital display

- power distribution: 8kw/M ,weight: 400(kg/M)

- furnace material: Q235 plate, the surface is sprayed by high temperature paint

- the cover is made of stainless steel (304)

- insulation material : inorganic cotton, aluminium silicate, good insulation and flame resistance. The difference of outside oven temperature and ambient temperature are no more than10℃

- adopt non health corner design, safe, healthy

- it has emergency stop switch, security protectors, such as auto alarm.

- the circuit configuration is beautiful, wire casing is made of aluminium alloy

- control apparatus by Germany brand Siemens

- bearings by Japan brand NSK.

Cooling machine

Features:

it is used for cooling and conveying the biscuits in normal condition. parameters:

- it can be designed straight type, "Z" type or suspension type air-right structure according to customer's request

- belt roller diameter:Ø150,covered with rubber, single side thickness 10mm

- sectional dimension:700X850 weight:0.4(T/M),power:0.37KW

- conveyor belt: food grade PU belt,thickness1.3mm,width1100mm,offset adjusted and tensioned manually.

- transition way: small roller smooth transition,transition knife diameter:Ø16

- frame plate and supporting plate are made of stainless steel

- cylinder by Korea brand YSC

- adopt non health corner design, safe, healthy

- it has security protectors, such as emergency stop switch.

- Main motor and reducer by SEW, frequency speed-regulator

- the circuit configuration is beautiful, wire casing is made of aluminum alloy

- main control apparatus by SCHNEIDER

- bearings by Japan brand NSK