Dust collector

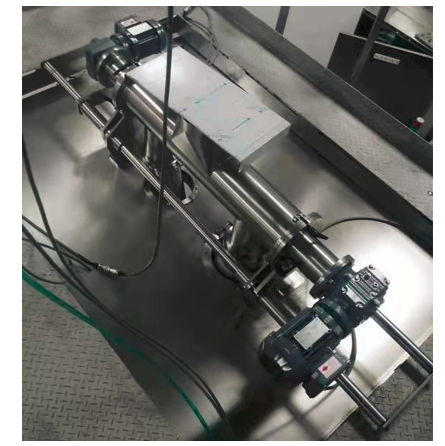

Equipment Description

Under pressure, the dusty gas enters the dust collector through the air inlet. At this time, the airflow expands and the flow rate decreases, which will cause large particles of dust to be separated from the dusty gas under the action of gravity and fall into the dust collection drawer. The rest of the fine dust will adhere to the outer wall of the filter element along the direction of the airflow, and then the dust will be cleaned by the vibrating device. The purified air passes through the filter core, and the filter cloth is discharged from the air outlet at the top.

Main Features

1. Exquisite atmosphere: the whole machine (including the fan) is made of stainless steel, which meets the food-grade working environment.

2. Efficient: Folded micron-level single-tube filter element, which can absorb more dust.

3. Powerful: Special multi-blade wind wheel design with stronger wind suction capacity.

4. Convenient powder cleaning: One-button vibrating powder cleaning mechanism can more effectively remove the powder attached to the filter cartridge and remove dust more effectively.

5. Humanization: add a remote control system to facilitate remote control of equipment.

6. Low noise: special sound insulation cotton, effectively reduce noise.

Technical Specification

|

Model |

SP-DC-2.2 |

|

Air volume(m³) |

1350-1650 |

|

Pressure(Pa) |

960-580 |

|

Total Powder(KW) |

2.32 |

|

Equipment maximum noise(dB) |

65 |

|

Dust removal efficiency(%) |

99.9 |

|

Length(L) |

710 |

|

Width(W) |

630 |

|

Height(H) |

1740 |

|

Filter size(mm) |

Diameter 325mm,length800mm |

|

Total weight (Kg) |

143 |