Gelatin Extruder-Scraped Surface Heat Exchangers-SPXG

Description

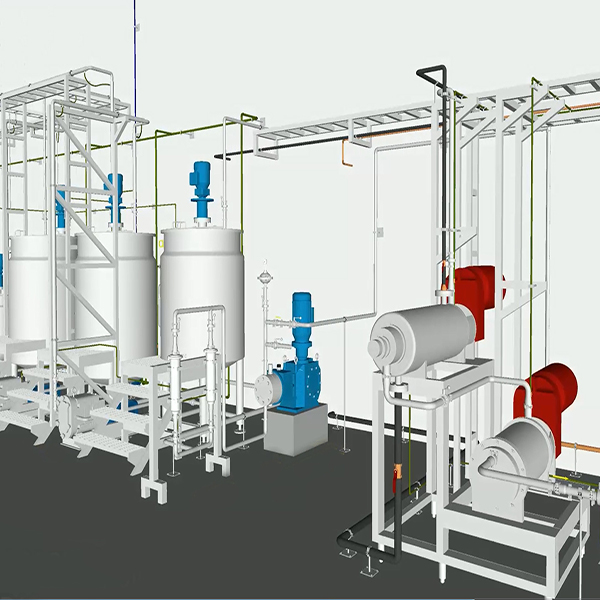

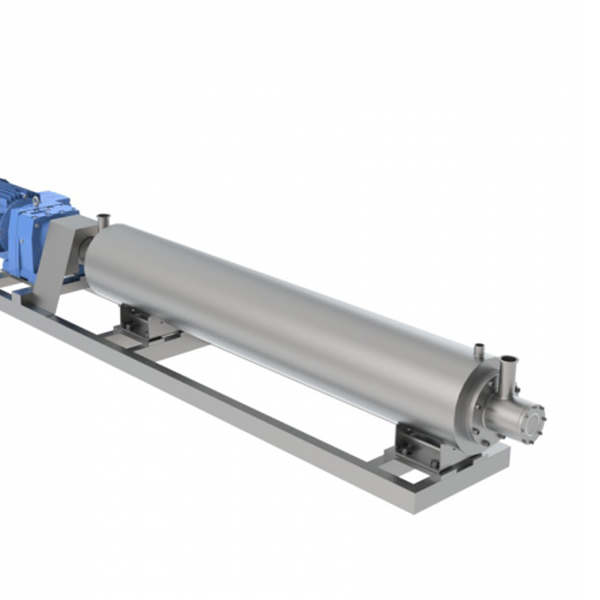

The extruder used for gelatin is actually a scraper condenser, After evaporation, concentration and sterilization of gelatin liquid (general concentration is above 25%, temperature is about 50℃), Through health level to the high pressure pump dispensing machine imports, at the same time, cold media (generally for ethylene glycol low temperature cold water) pump input outside bile within the jacket fits to the tank, to instant cooling of hot liquid gelatin, squeezed through the front end under the pressure of high pressure pump setting nets take orifice into strips, in the process of cooling, due to the heat exchange tube wall because of the action of main shaft on the scraper, The gelatin liquid is constantly heat exchange, and will not coagulate on the inner wall of the heat exchange tube, so as to complete the gelatin forming process.

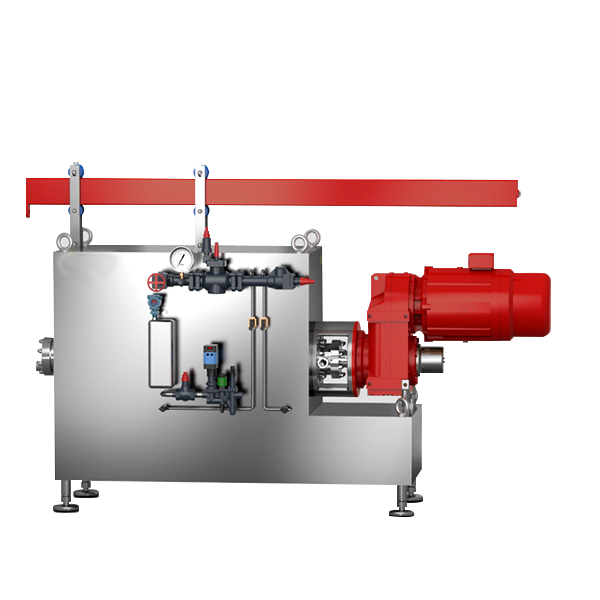

Control mode: automatic control, automatic temperature control, automatic swing control: scraping heat exchanger, swing system, feed water pump, frame structure, pipe and automatic temperature control. It is made of high quality stainless steel.

At the end of the sterilization process, the gelatin solution is cooled using scratch surface heat exchangers, also known by different manufacturers as "votator", "gelatin extruder" and "chemetator".

Technical spec.

| Heat Exchange Area | 1.0m2, 0.8m2, 0.7m2, 0.5m2. |

| Annular Space | 20mm |

| Scraper Material | PEEK |

| Pressure of Material Side | 0~4MPa |

| Mechanical Seal Material | Silicon Carbide |

| Pressure of Media Side | 0~0.8MPa |

| Brand of Reducer | SEW |

| Rotating Speed of Main Shaft | 0~100r/min |

| Working Pressure | 0~4MPa |