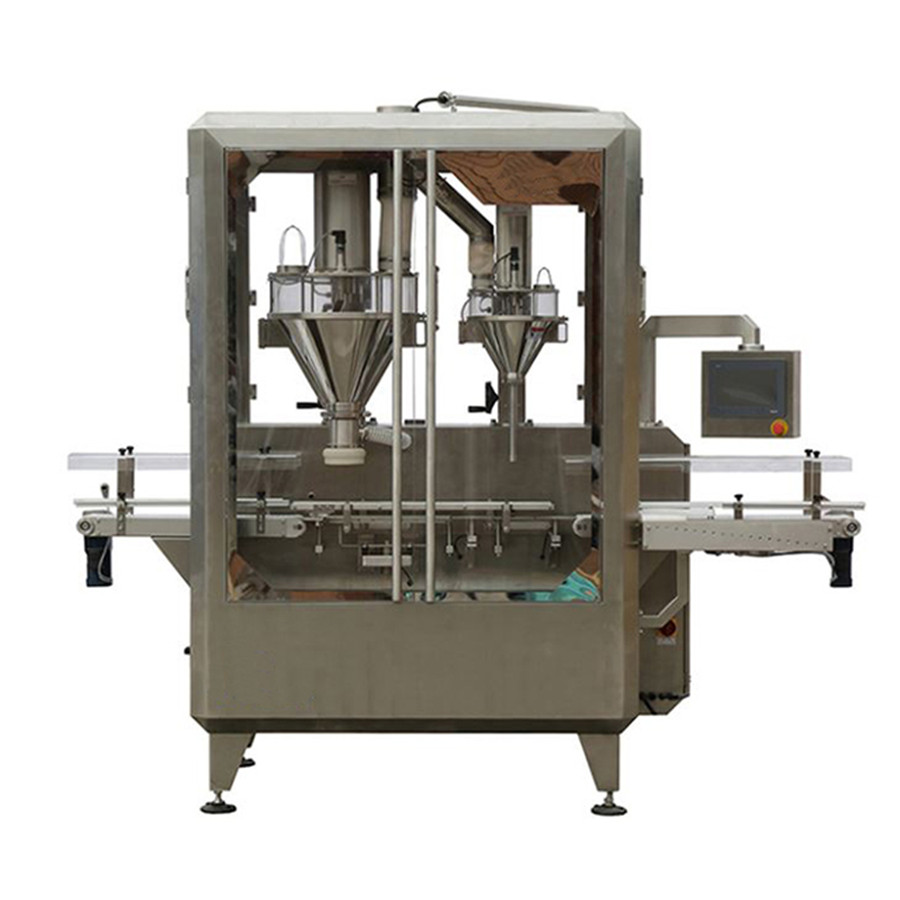

High Performance China Automatic Can/Tin Powder Filling Machine

“Sincerity, Innovation, Rigorousness, and Efficiency” would be the persistent conception of our corporation with the long-term to create collectively with buyers for mutual reciprocity and mutual advantage for High Performance China Automatic Can/Tin Powder Filling Machine, With a quickly enhancement and our customers come from Europe, United States, Africa and everywhere in the world. Welcome to go to our manufacturing unit and welcome your get, for more inquires be sure to never hesitate to get in touch with us!

“Sincerity, Innovation, Rigorousness, and Efficiency” would be the persistent conception of our corporation with the long-term to create collectively with buyers for mutual reciprocity and mutual advantage for Can Filling, China Filling Machine, Aiming to grow to be by far the most professional supplier within this sector in Uganda, we keep researching on the creating procedure and raising the high quality of our principal goods. Till now, the merchandise list has been updated on a regular basis and attracted customers from around the globe. Detailed data can be obtained in our web page and you’ll be served with good quality consultant service by our after-sale team. They’re going to allow you to get complete acknowledge about our items and make a satisfied negotiation. Small business check out to our factory in Uganda can also be welcome at any time. Hope to obtain your inquiries to get a happy co-operation.

Main features

One line dual fillers, Main & Assist can filling to keep work in high-precision.

Can-up and horizontal transmitting is controlled by servo and pneumatic system, be more accurate, more speed.

Servo motor and servo driver control the screw, keep stable and accurate

Stainless steel structure, Split hopper with polishing inner-out make it to cleaned easily.

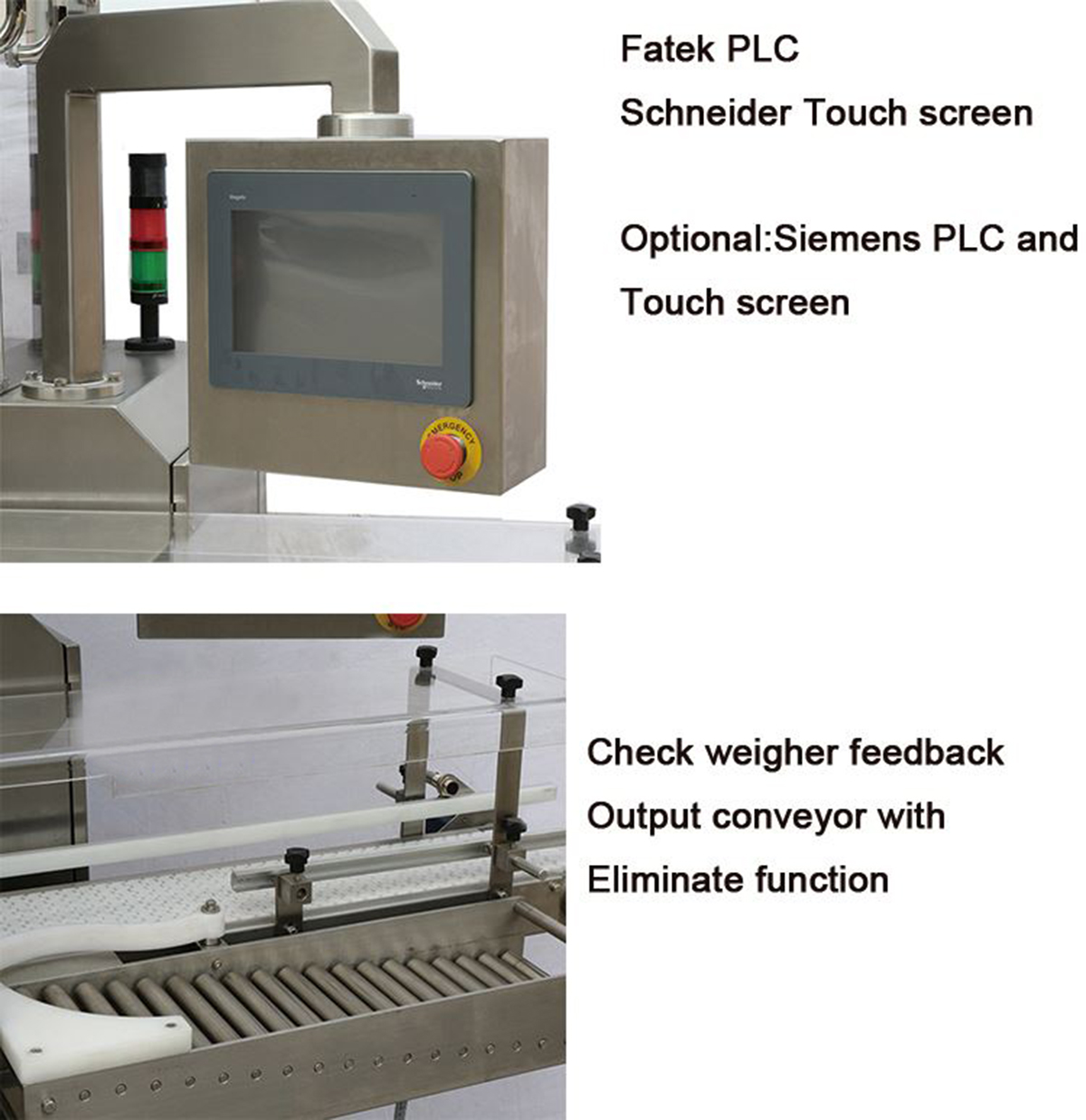

PLC & touch screen make it be easy of operation.

Fast-respond weighing system make the strongpoint to real

The handwheel make the exchange of different filings to be easily.

Dust-collecting cover meet the pipeline and protect environment to pollution.

Horizontal straight design make the machine in little area

Settled screw setup make no metal pollution in producing

Process: can-into → can-up → vibration →can filling → vibration → vibration → weighing & tracing → reinforce → weight checking → Can-out

With whole system central control system.

Main technical data

|

Dosing mode |

Dual filler can filling with online weighing |

|

Can Filling Weight |

100 – 2000g |

|

Container Size |

Φ60-135mm; H 60-260mm |

|

Can Filling Accuracy |

100-500g, ≤±1g; ≥500g,≤±2g |

|

Can Filling Speed |

Above 50 cans/min(#502),Above 60 cans/min(#300 ~ #401) |

|

Power Supply |

3P AC208-415V 50/60Hz |

|

Total Power |

3.4 kw |

|

Total Weight |

450kg |

|

Air Supply |

6kg/cm 0.2cbm/min |

|

Overall Dimension |

2650×1040×2300mm |

|

Hopper Volume |

50L(Main) 25L (Assist) |

Main function

High Performance China Filling Machine, Can Filling, Aiming to grow to be by far the most professional supplier within this sector in Uganda, we keep researching on the creating procedure and raising the high quality of our principal goods. Till now, the merchandise list has been updated on a regular basis and attracted customers from around the globe. Detailed data can be obtained in our web page and you’ll be served with good quality consultant service by our after-sale team. They’re going to allow you to get complete acknowledge about our items and make a satisfied negotiation. Small business check out to our factory in Uganda can also be welcome at any time. Hope to obtain your inquiries to get a happy co-operation.