Metal Detector

Basic Information of Metal Separator

1) Detection and separation of magnetic and non-magnetic metal impurities

2) Appropriate for powder and fine-grained bulk material

3) Metal separation using a reject flap system (“Quick Flap System”)

4) Hygienic design for easy cleaning

5) Meets all IFS and HACCP requirements

6) Complete Documentation

7) Outstanding ease of operation with product auto-learn function and latest microprocessor technology

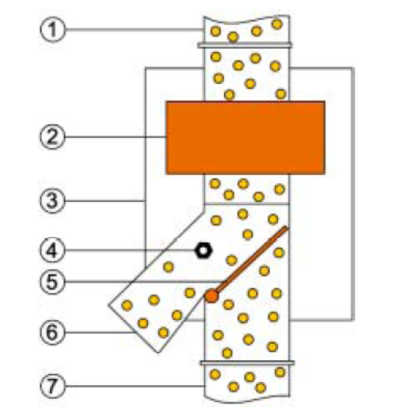

II.Working Principle

① Inlet

② Scanning Coil

③ Control Unit

④ Metal impurity

⑤ Flap

⑥ Impurity Outlet

⑦ Product Outlet

Product falls through the scanning coil ②, when metal impurity④ is detected, the flap ⑤is activated and metal ④ is ejected from impurity outlet⑥.

III.Feature of RAPID 5000/120 GO

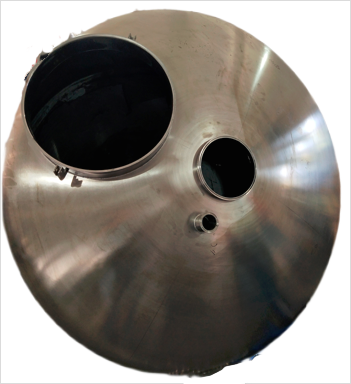

1) Diameter of the Pipe of Metal Separator: 120mm; Max. Throughput: 16,000 l/h

2) Parts in touch with material: stainless steel 1.4301(AISI 304), PP pipe, NBR

3) Sensitivity adjustable: Yes

4) Drop height of bulk material : Free fall, maximum 500mm above equipment top edge

5) Max Sensitivity: φ 0.6 mm Fe ball, φ 0.9 mm SS ball and φ 0.6 mm Non-Fe ball(without consideration of product effect and ambient disturbance)

6) Auto-learn function: Yes

7) Type of protection: IP65

8) Reject duration: from 0.05 to 60 sec

9) Compression air: 5 - 8 bar

10) Genius One control unit: clear and fast to operate on 5“ touchscreen, 300 product memory, 1500 event record, digital processing

11) Product tracking: automatically compensate slow variation of product effects

12) Power supply: 100 - 240 VAC (±10%), 50/60 Hz, single phase. Current consumption: approx. 800 mA/115V , approx. 400 mA/230 V

13) Electrical connection:

Input:

“reset” connection for possibility of an external reset button

Output:

2 potential-free relay switchover contact for external “metal” indication

1 potential- free relay switchover contact for external “error” indication