Milk Powder Vacuum Can Seaming Chamber China Manufacturer

Equipment Description

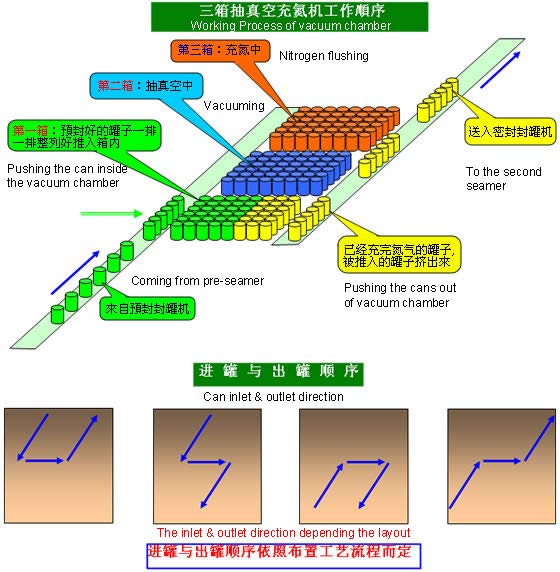

This high speed vacuum can seamer is new type of vacuum can seaming machine designed by our company. It will coordinate two sets of normal can seaming machines. The can bottom will be pre-sealed first, then fed into the chamber for vacuum suction and nitrogen flushing, after that the can will be sealed by the second can seamer to complete the full vacuum packaging process.

Compared with combined vacuum can seamer, the equipment have obvious advantage as below,

- High speed : the speed of combined vacuum can seamer is 6-7cans/min, our machine is above 30cans/min.;

- Steady operation: no can jam;

- Low cost: about 20% of combined vacuum can seamer on base of same capacity;

- Low consumption of vacuum and nitrogen;

- Low milk powder overfalling, within 1g for 10,000 cans, more clean;

More easy operation and maintenance;

Technical Specification

- Production speed: above 30cans/min.

- RO: ≤2%

- Flying powder: within 1g/10000cans

- Including one pc of CO2 mixing flowmeter and 0.6 M3 of CS air storage tank

- Power: 2.8kw

- Air consumption: 0.6M3/min, 0.5-0.6Mpa

- N2 consumption: 16M3/h, 0.1-0.3Mpa

- CO2consumption: 16M3/h, 0.1-0.3Mpa

Working Process

Write your message here and send it to us

Products categories

Write your message here and send it to us