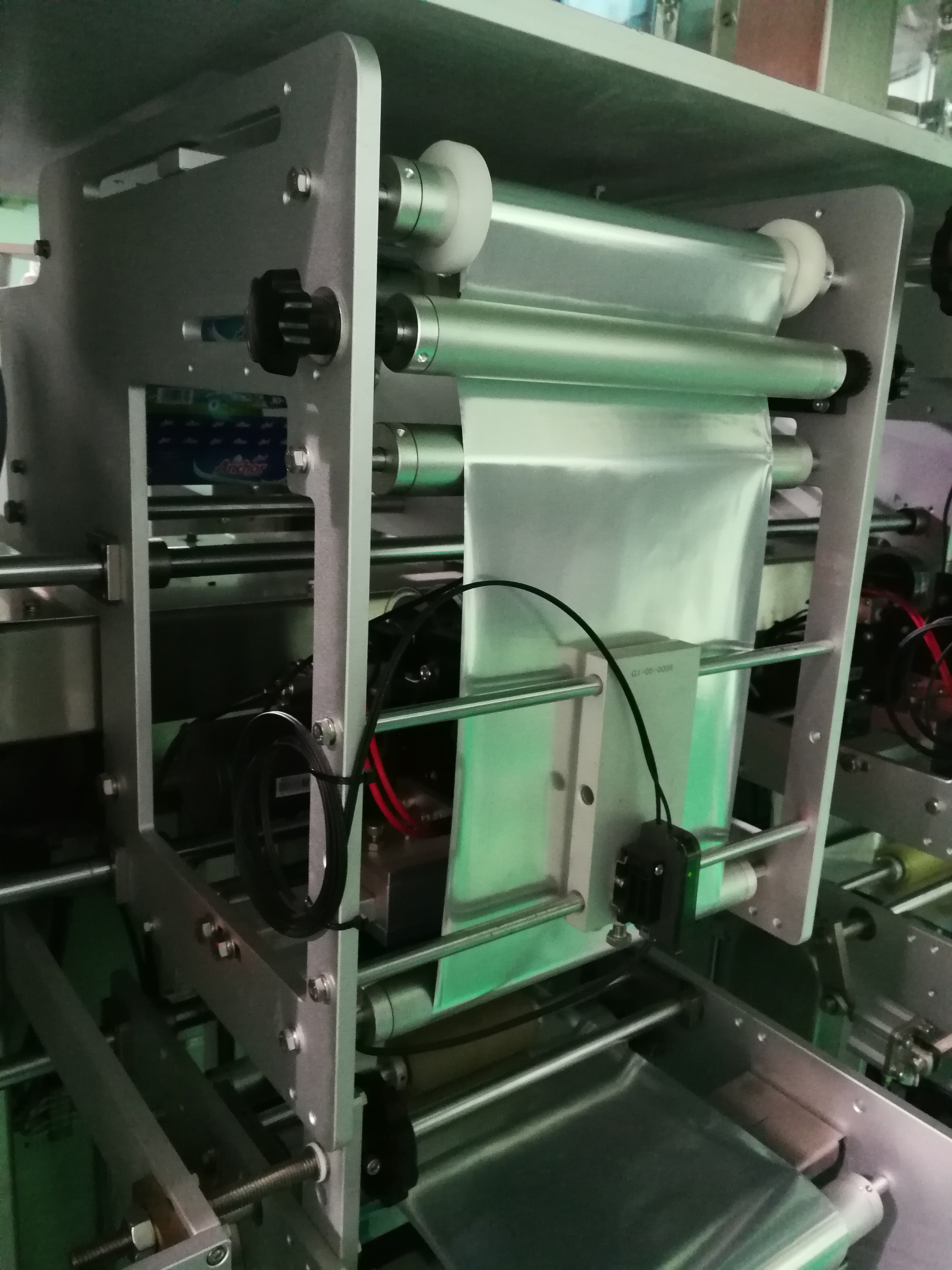

Multi Lane Sachet Packaging Machine Model: SPML-240F

Video

Equipment Description

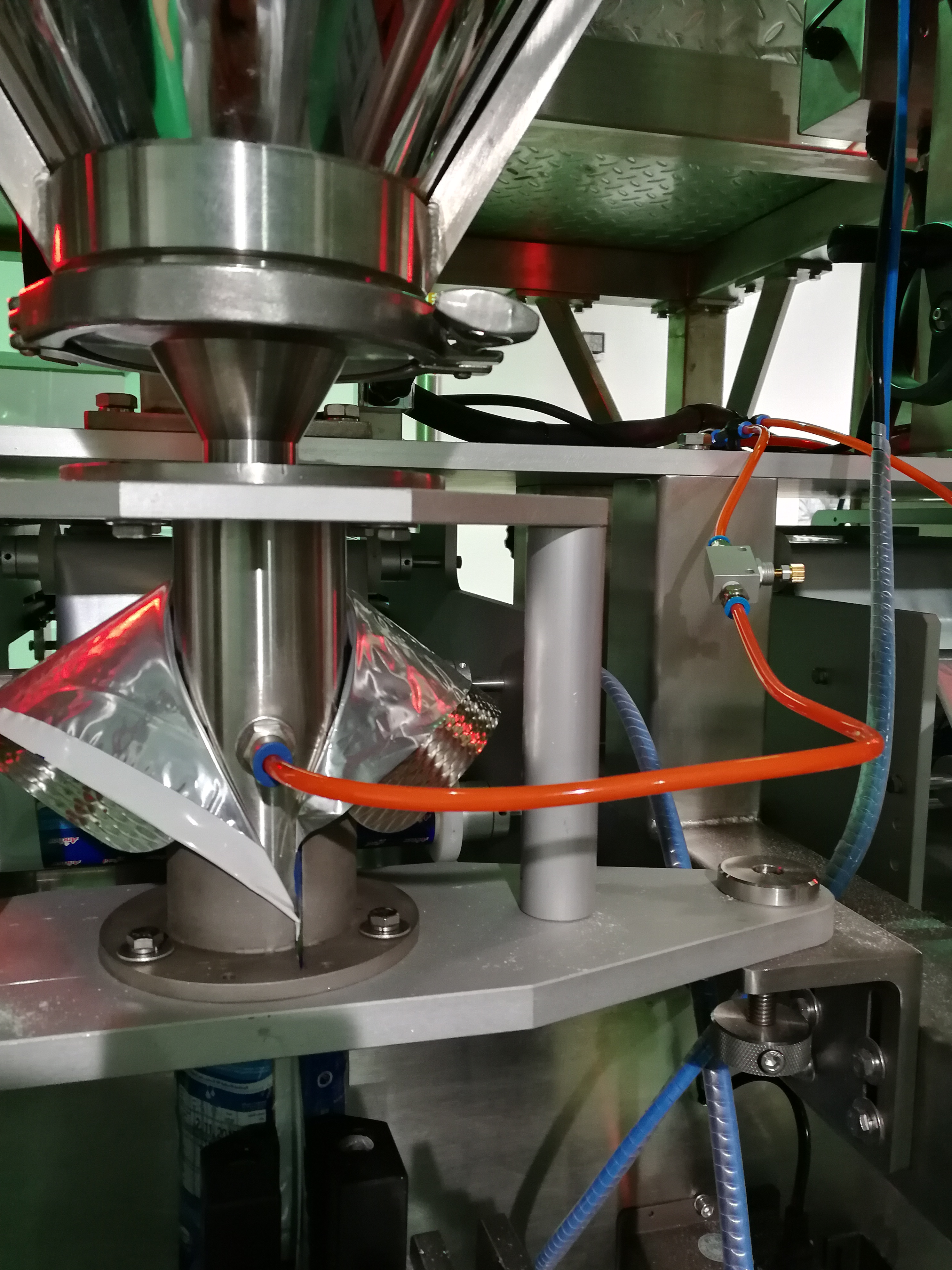

Multi-lane powder sachet packaging machine

This powder sachet packaging machine completes the whole packaging procedure of measuring, loading materials, bagging, date printing, charging (exhausting) and products transporting automatically as well as counting. can be used in powder and granular material. like milk powder, Albumen powder, solid drink, white sugar, dextrose, coffee powder, and so on.

Main features

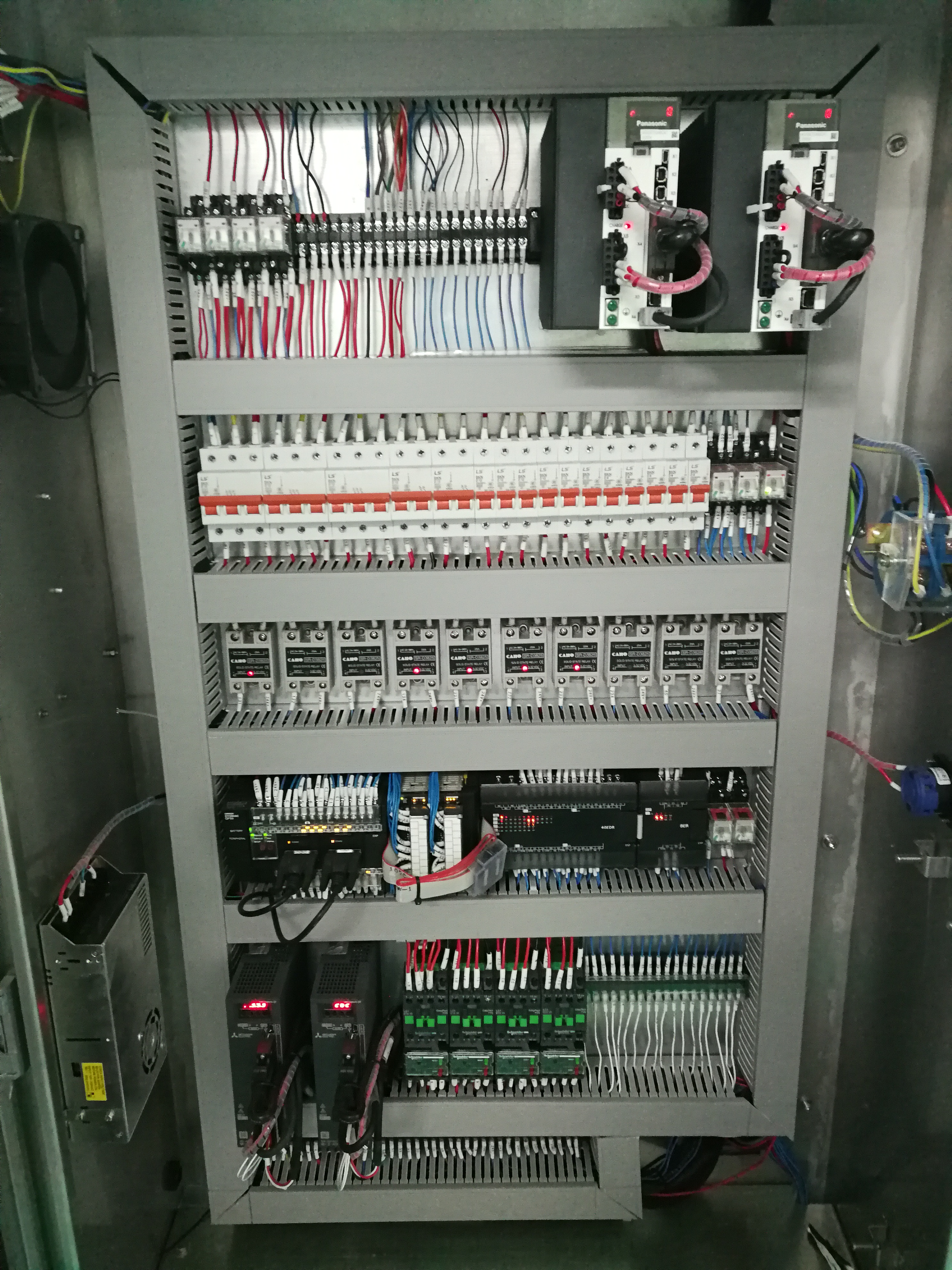

Omron PLC controller with touch screen interface.

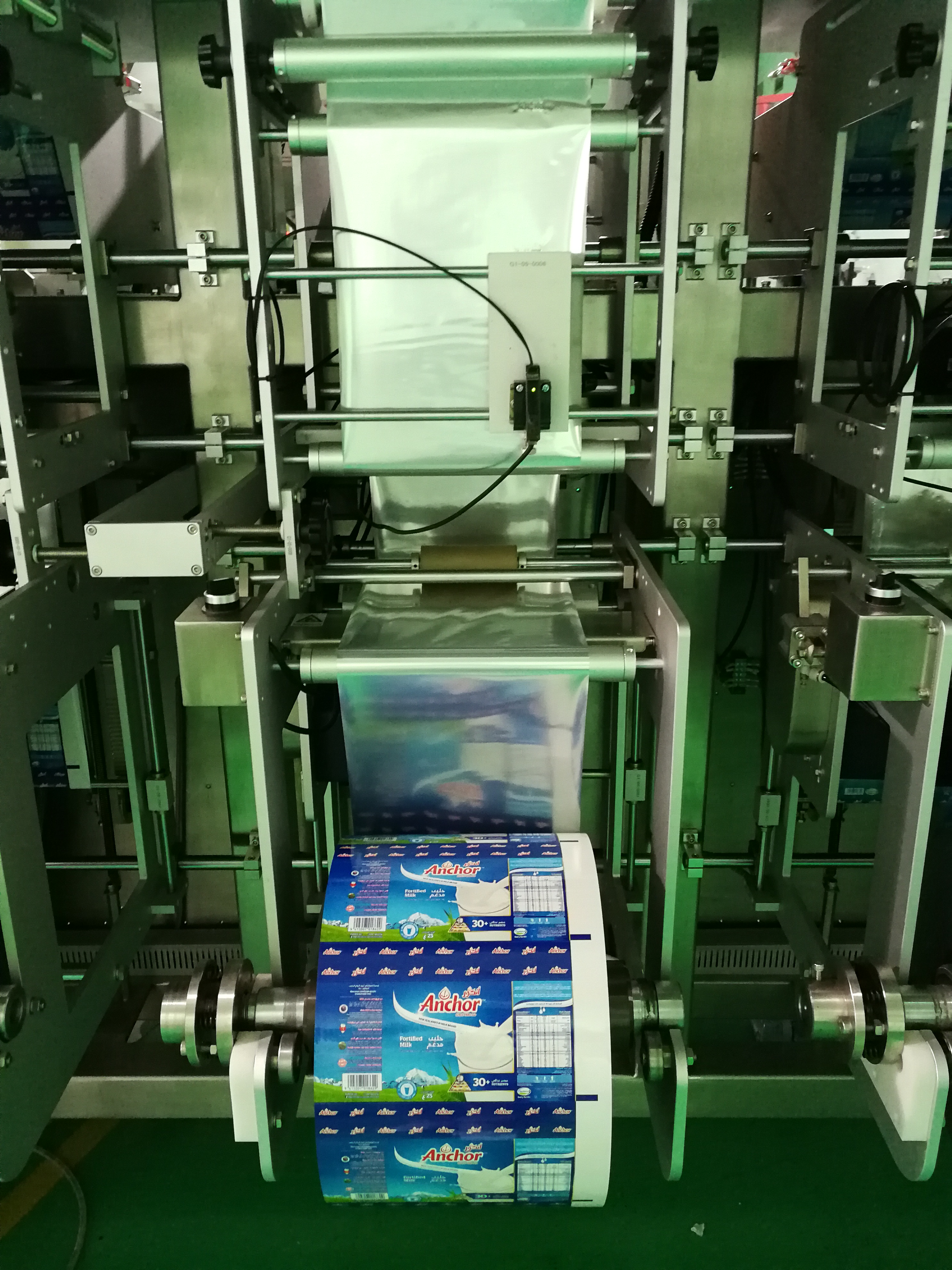

Panasonic/Mitsubishi servo-driven for film pulling system.

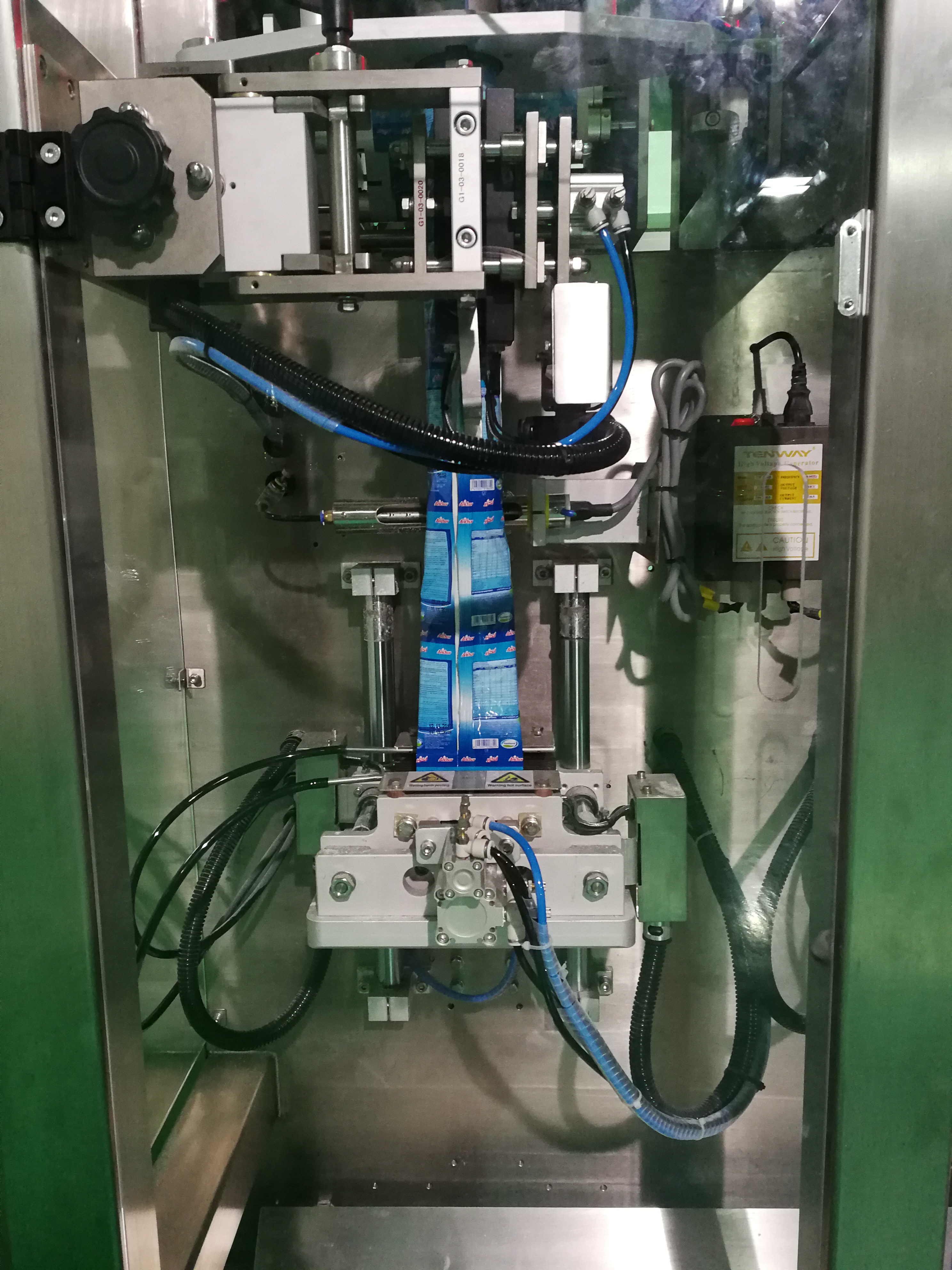

Pneumatic driven for horizontal end sealing.

Omron temperature control table.

Electric Parts use Schneider/LS brand.

Pneumatic components use SMC brand.

Autonics brand Eye mark sensor for controlling the packing bag length size.

Die-cut style for round corner, with high firmness and slice the side smooth.

Alarm function: Temperature

No film run automatic alarming.

Safety warning labels.

Door protection device and interaction with PLC control.

Main function

Empty bag preventive device;

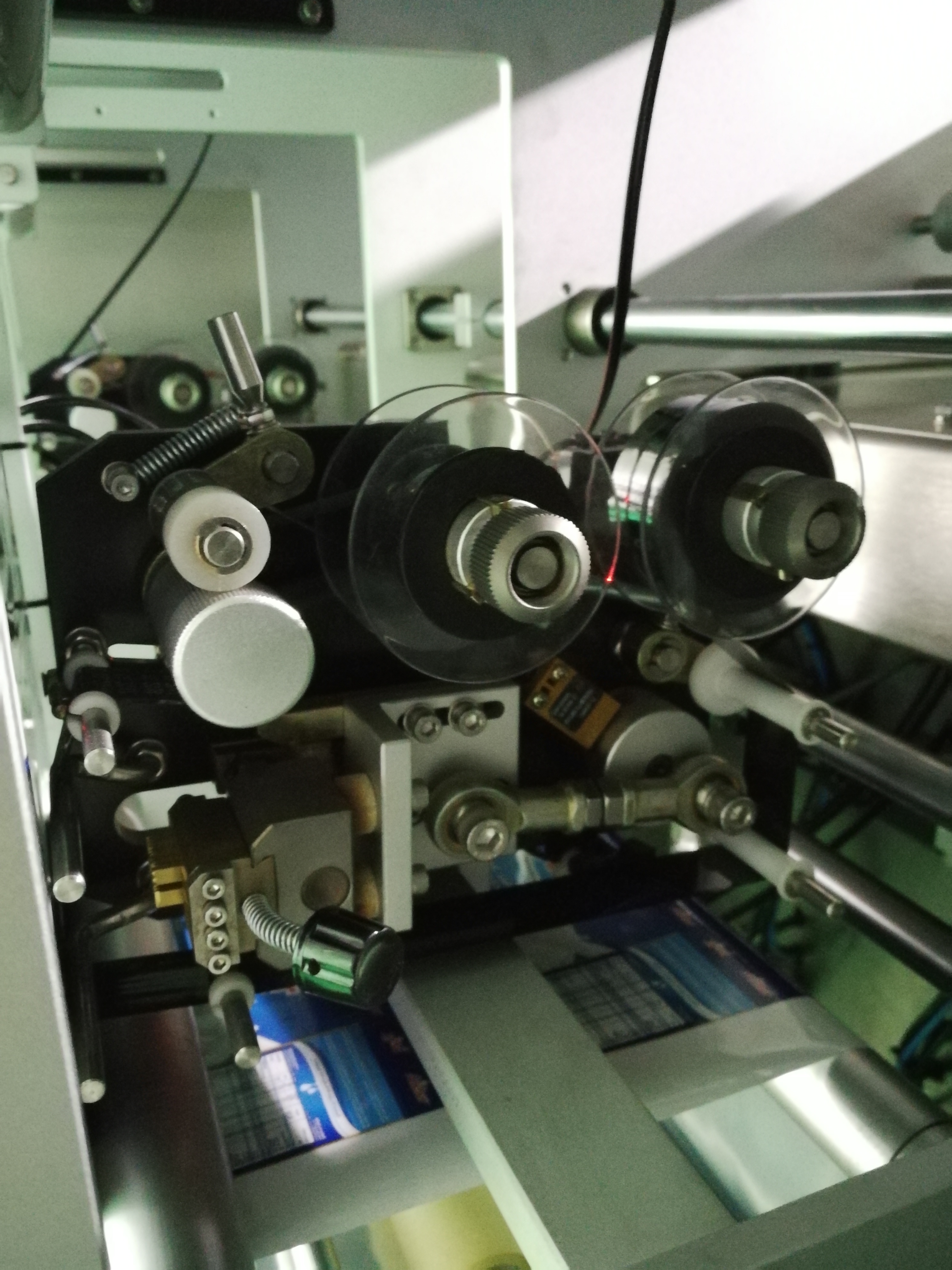

Printing mode matching: Photoelectric sensor detect;

Dosing synchronous sending signal 1:1;

Bag length adjustable mode: Servo motor;

Machine automatic stop function

Packing film end

Printing band end

Heater error

Air pressure low

Band printer

Film pulling motor, Mitsubishi: 400W, 4 units/set

Film output, CPG 200W, 4 units/set

HMI: Omron, 2 units/set

The configuration could be optional as per customer's requirements

Technical specification

|

Dosing mode |

Auger filler |

|

Bag Type |

stick bag, sachet, pillow bag,3 side sachet,4 side sachet |

|

Bag Size |

L:55-180mm W:25-110mm |

|

Film Width |

60-240mm |

|

Filling Weight |

0.5-50g |

|

Packaging Speed |

110-280 bags/min |

|

Packaging Accuracy |

0.5 – 10g, ≤±3-5%;10 - 50g, ≤±1-2% |

|

Power Supply |

3P AC208-415V 50/60Hz |

|

Total Power |

15.8kw |

|

Total Weight |

1600kg |

|

Air Supply |

6kg/m2 , 0.8m3/min |

|

Overall Dimension |

3084×1362×2417mm |

|

Hopper Volume |

25L |