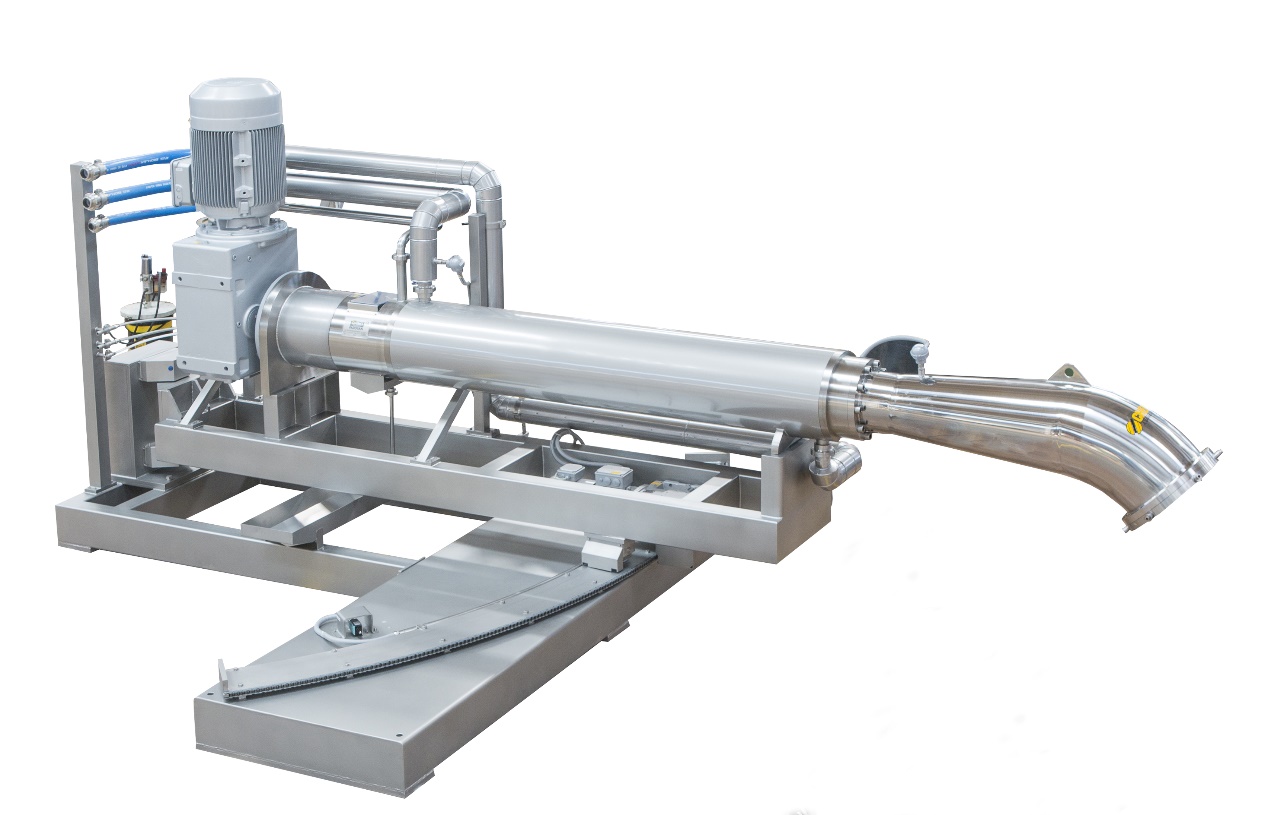

After the sterilization process, the gelatin solution is chilled using a scraped surface heat exchanger, called”votator”, “gelatin extruder” or “chemetator” by different manufacturers as well.

During this process, the highly concentrated solution is gelled and is extruded in the form of noodles that are transferred directly to the belt of continuous band dryer. A specially designed oscillating system is applied for spreading the gelled noodles to the dryer’s belt instead of transferring by conveyor, by this way, contamination is avoided.

The key part for the gelatin votator is the horizontal heat transfer cylinder, jacketed for direct expansion refrigerant. Inside the cylinder, is a shaft rotating at a certain speed with scraper blades continuously scraping the internal surface the cylinder.

The scraped surface heat exchanger (gelatin votator) is widely used for cooling gelatin adopted by all the modern gelatin factories. The highly concentrated gelatin solution from evaporator and sterilization process to be continuously chilled and then gelled in the insulated holding cylinder before being extruded in noodles form direct onto the continuous band dryer.

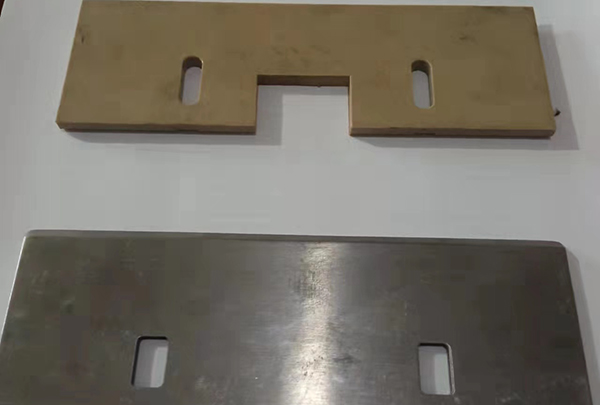

There are scraper blades made of wear-resistant material mounted on the main shaft. And main shaft an easily be removed from its bearing and coupling support for cleaning, inspection and maintenance.

The removable heat transfer tubes are normally made of nickel for optimal efficiency and wear resistance by liquid coolant such as glycol and brine.

Hebei Shipu Machienry Technology Co., Ltd., which has 20 years’ of manufacture experience of votator and scraped surface heat exchanger in China, can provide one stop service for margarine production, shortening processing, gelatin production and related dairy product. We not only provide complete margarine production line, but also provide technical service to our customers, like market research, recipe design, production supervision and other after sale service.

Post time: Jun-29-2022