A scraped surface heat exchanger (SSHE or Votator) is a type of heat exchanger used for processing viscous and sticky materials that tend to adhere to the heat transfer surfaces. The primary purpose of a scraped surface heat exchanger (votator) is to effectively heat or cool these challenging materials while preventing them from fouling or building up on the heat transfer surfaces. The scraper blades or agitators inside the exchanger continuously scrape the product off the heat transfer surfaces, maintaining efficient heat transfer and preventing any undesirable deposits.

Scraped surface heat exchangers (votator) are commonly used in various industries, including food processing, pharmaceuticals, chemicals, and petrochemicals, where materials like pastes, gels, waxes, creams, and polymers need to be heated, cooled, or crystallized without fouling the heat exchanger surfaces.

There are different configurations of scraped surface heat exchangers (votator), including:

Horizontal Scraped Surface Heat Exchanger (votator) : These have a horizontal cylindrical shell with rotating scraper blades inside.

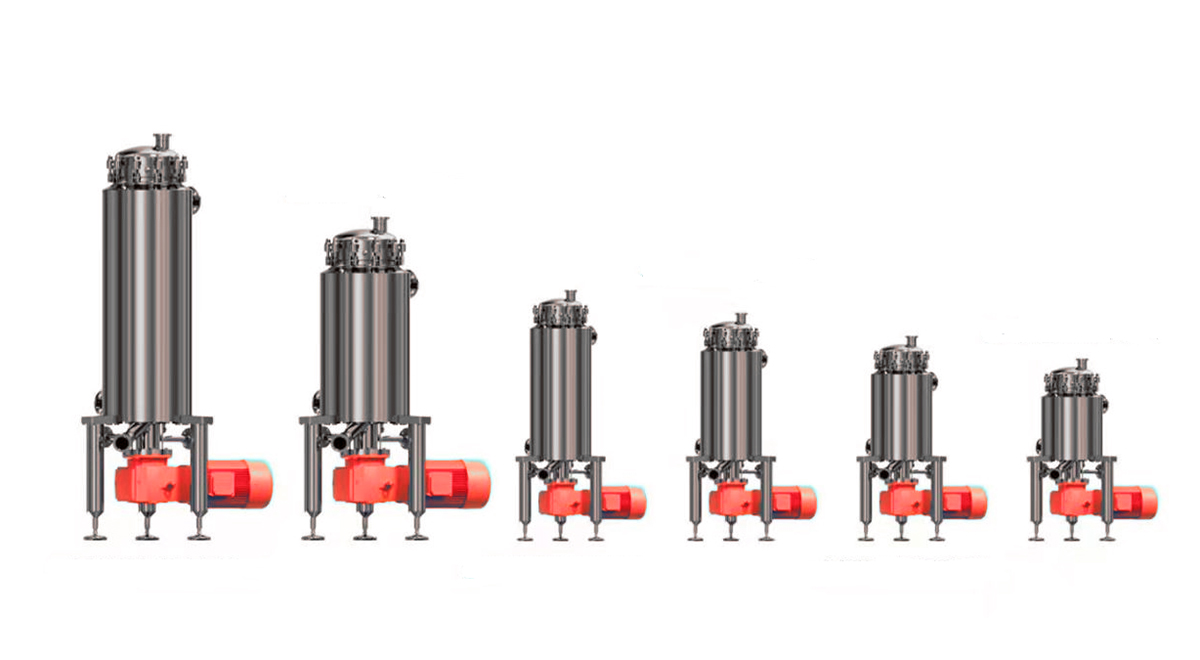

Vertical Scraped Surface Heat Exchanger (votator) : In this type, the cylindrical shell is vertical, and the scraper blades are placed vertically.

Double-Pipe Scraped Surface Heat Exchanger (votator): It consists of two concentric pipes, and the material flows in the annular space between the two pipes while the scraper blades agitate the product.

The design of scraped surface heat exchangers (votator) can vary depending on the specific application and the characteristics of the material being processed. They are chosen when conventional heat exchangers cannot effectively handle the challenges posed by highly viscous or sticky substances.

Post time: Apr-09-2024